- INJ Nagato Build -

INJ Nagato – Tyler (launched 2010, major refit 2013)

6.0 units, 24 seconds, Japanese Battleship

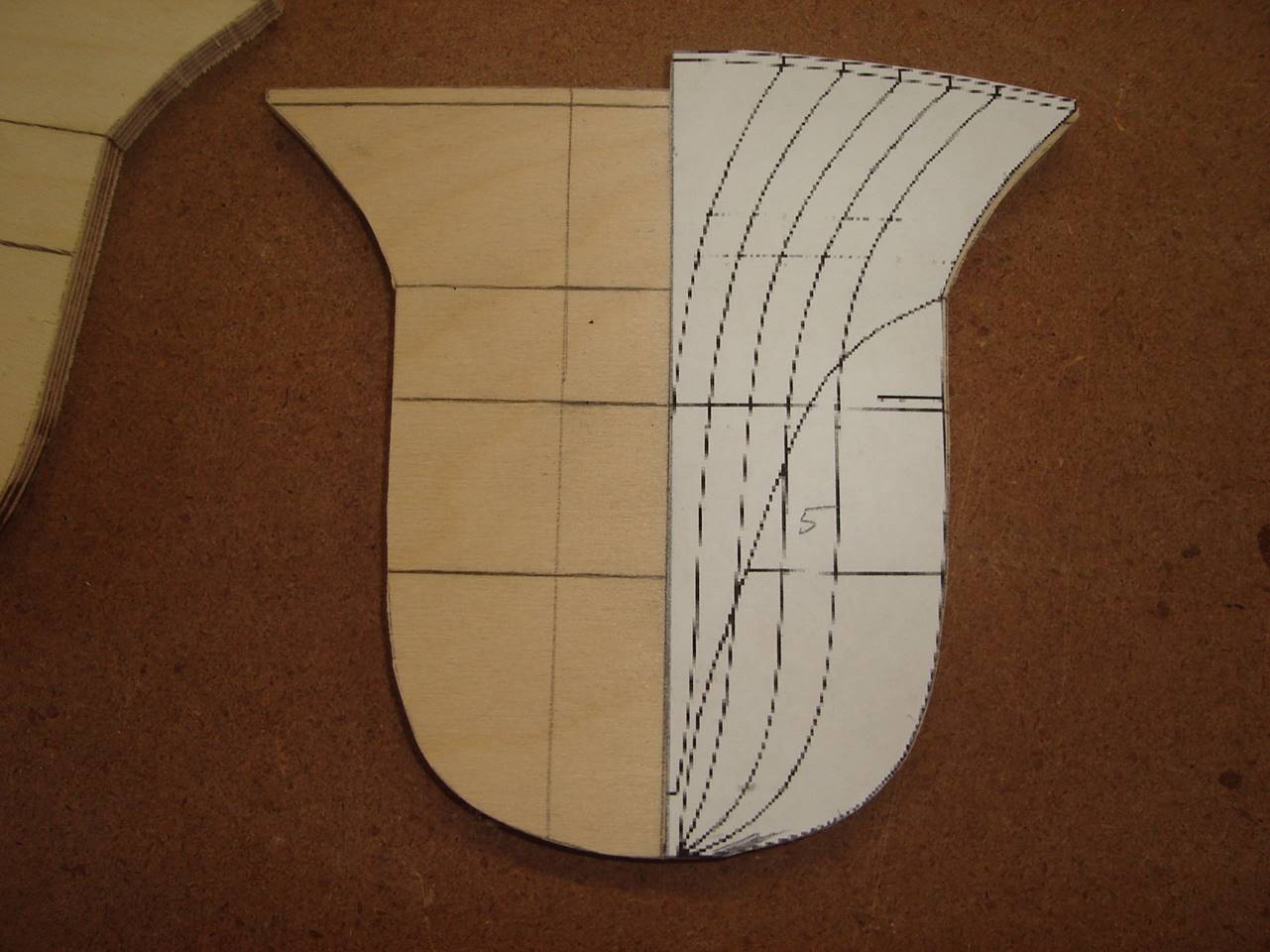

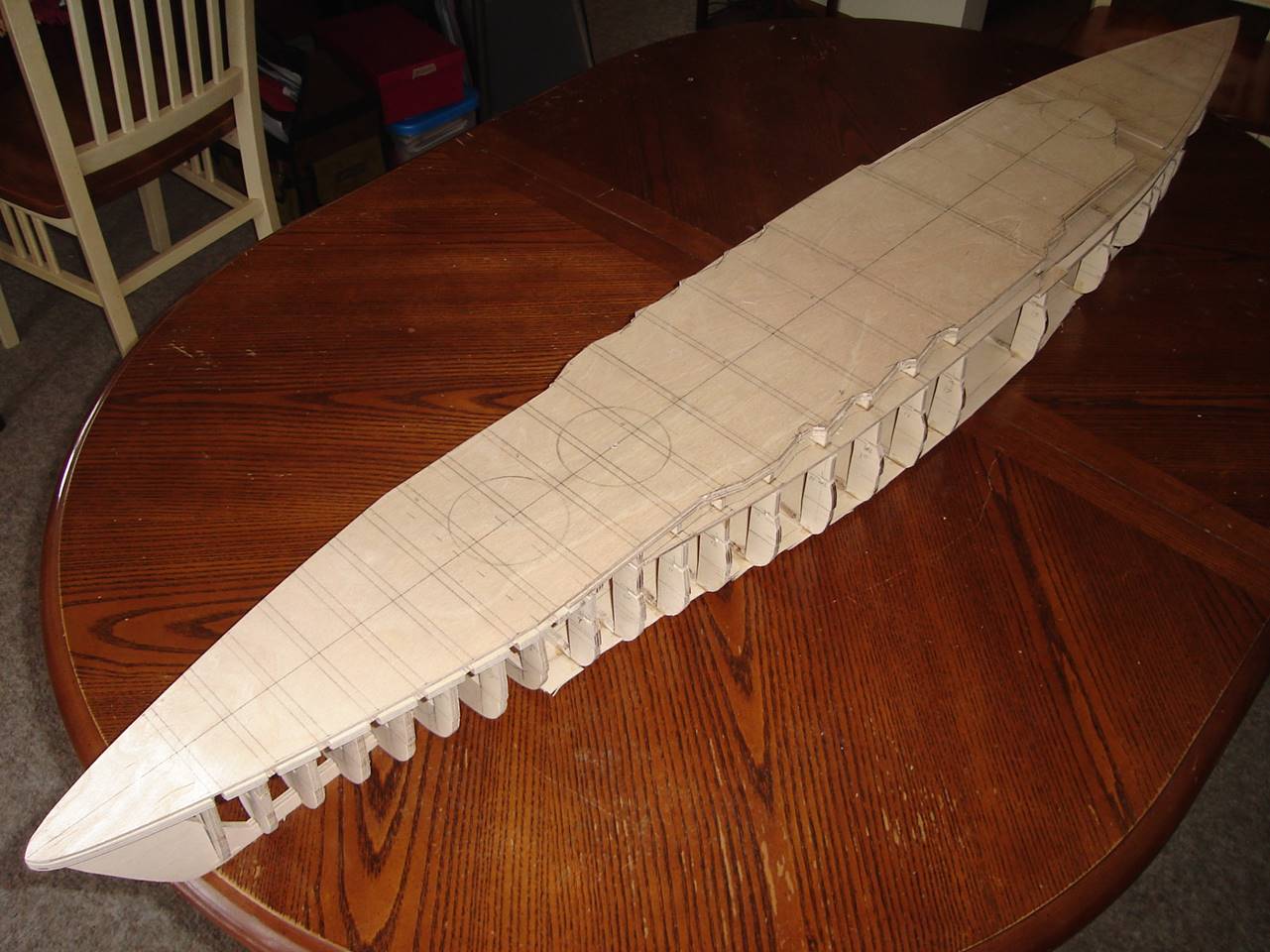

Wood ships start as a set of plans that are developed into

ribs. Larger ships are probably better using a base board (in this case ¼ inch

ply wood) so that the water channeling can be directly cut out and incorporated

into the build from the early stages and it allows for a very solid foundation.

Some smaller ships like cruisers can be built upside down right onto the sub

deck and planked, later fiber glassing over it all. Just like with fiberglass

kits, a lot of factors contribute to where ribs should be placed – the bow and

the hull under the sidemoutns generally collect more

damage so more ribs can help keep some bb’s out, some hulls are very curvy and

need more ribs to hold odd shapes and curves, some hull features such as steps

and casemates allow for good areas to put ribs as well. Usually 4 inches apart is

about as maximally spaced as I would recommend and the rules dictate that they

can be no closer than 1 inch together. The number of ribs is generally 85% of

the total of the hull minus 2 inches in the bow and 1 in the stern, multiple

the remaining inches by 4 to get the number of ¼ inch ribs. For the Nagato I

weighted the density of ribs to favor the bow and under the sidemounts,

lined a few of them up to go along the casemates, and left the far stern

relatively open. Not every location that I wanted a rib had a rib on the hull

lines, so I had to make extrapolations. Most hull line sets come with just ½

the plan so I had to flip the pattern to get the other side. I’ve also done

this process digitally so that I have the whole rib on one piece of paper. Technology

is making it easier and cheaper to directly program and laser cut ribs and

decks as well. The ribs, subdeck, and base board are made from ¼ inch 5 ply

birch plywood. The deck itself is 1/8 inch 5 ply birch

plywood.

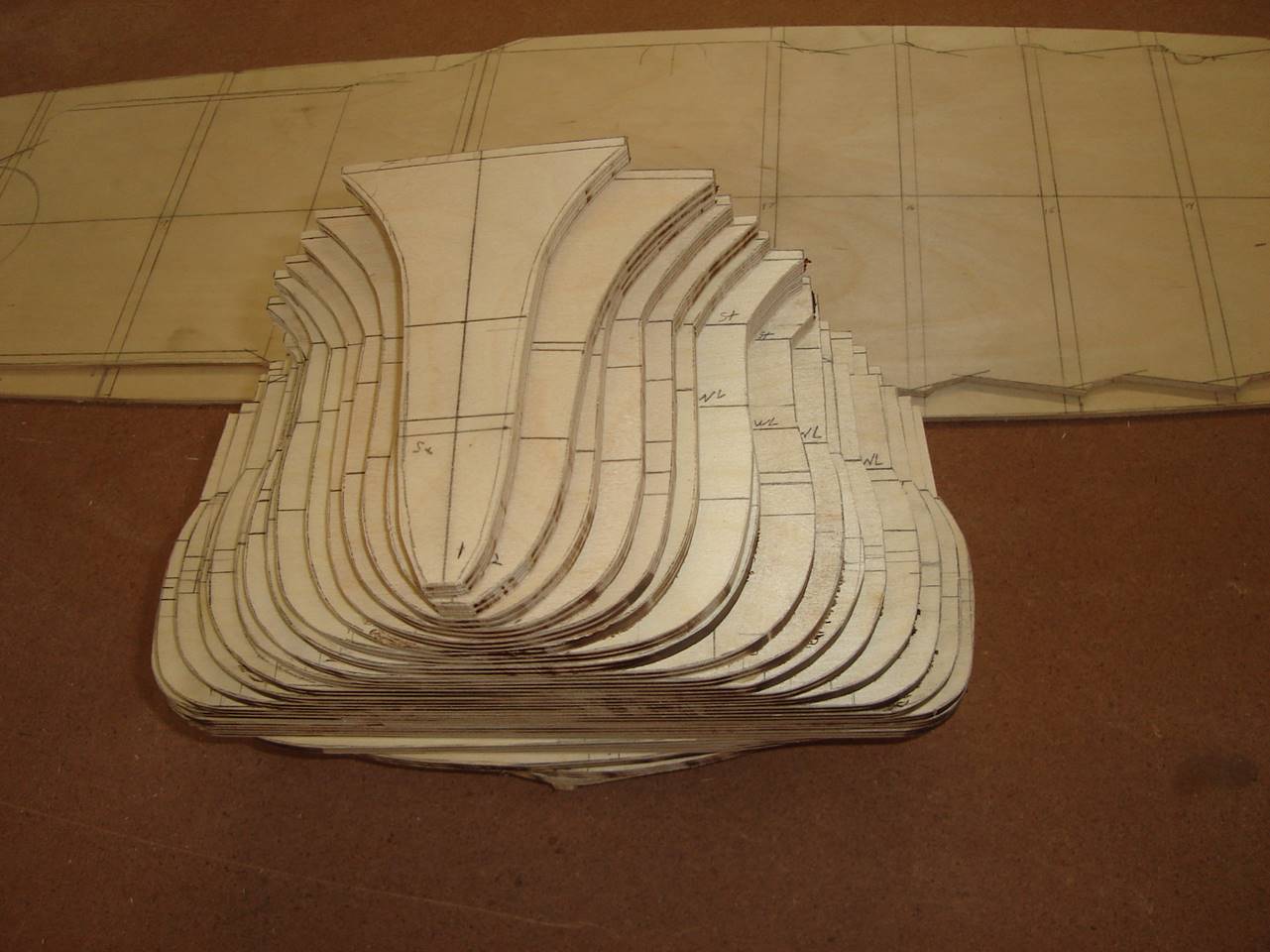

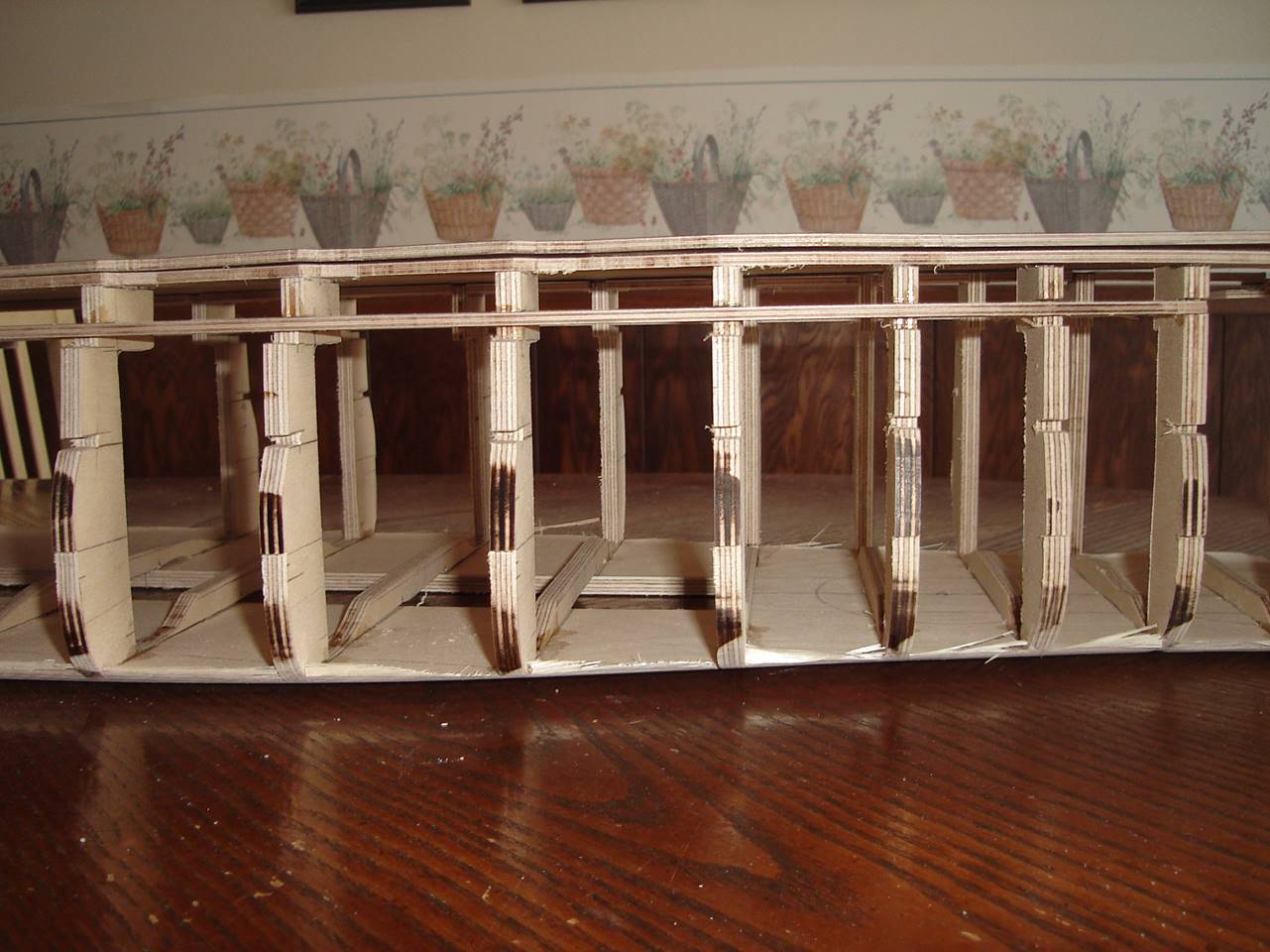

This is the full stack of ribs. I would advise marking

the waterline and the 1 inch below on every rib, the vertical centerline, as

well as the location of any other features such as stringers before gluing them

into the hull. I usually cut with a scroll saw and sand the edges to shape.

After they are glued in they will require a little

more sanding to make them all line up flush. Also the

middle of each rib needs to be cutout, with consideration of how thick the ribs

will be. 1 inch is plenty for most ships and 3/8 will suffice for most. Part of

the consideration is to make the ribs as thick as you want bulge water

channeling in the widest part of the ship. In the far bow and stern I fill in

the entire below the water line portion with balsa to act as water channeling.

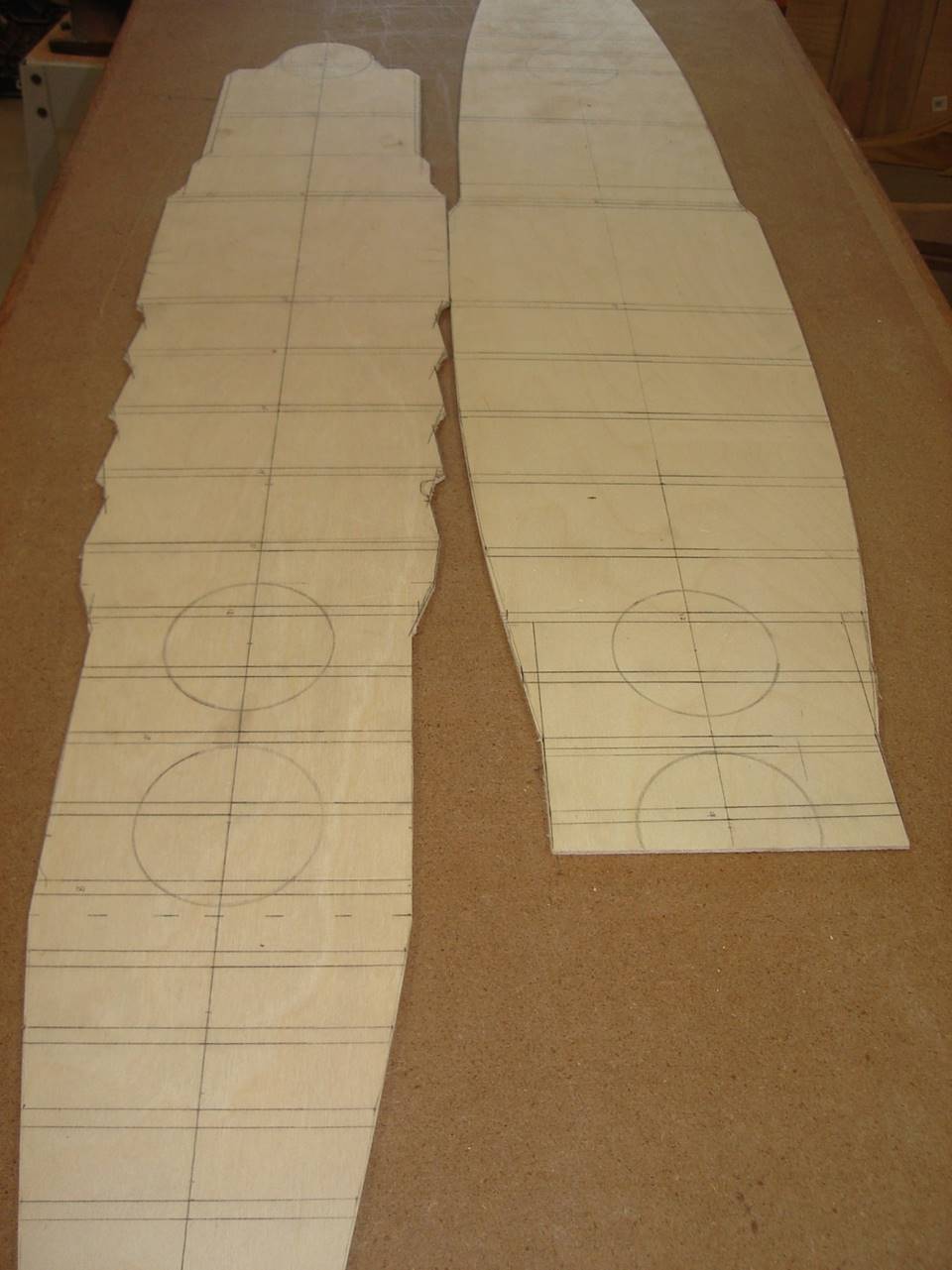

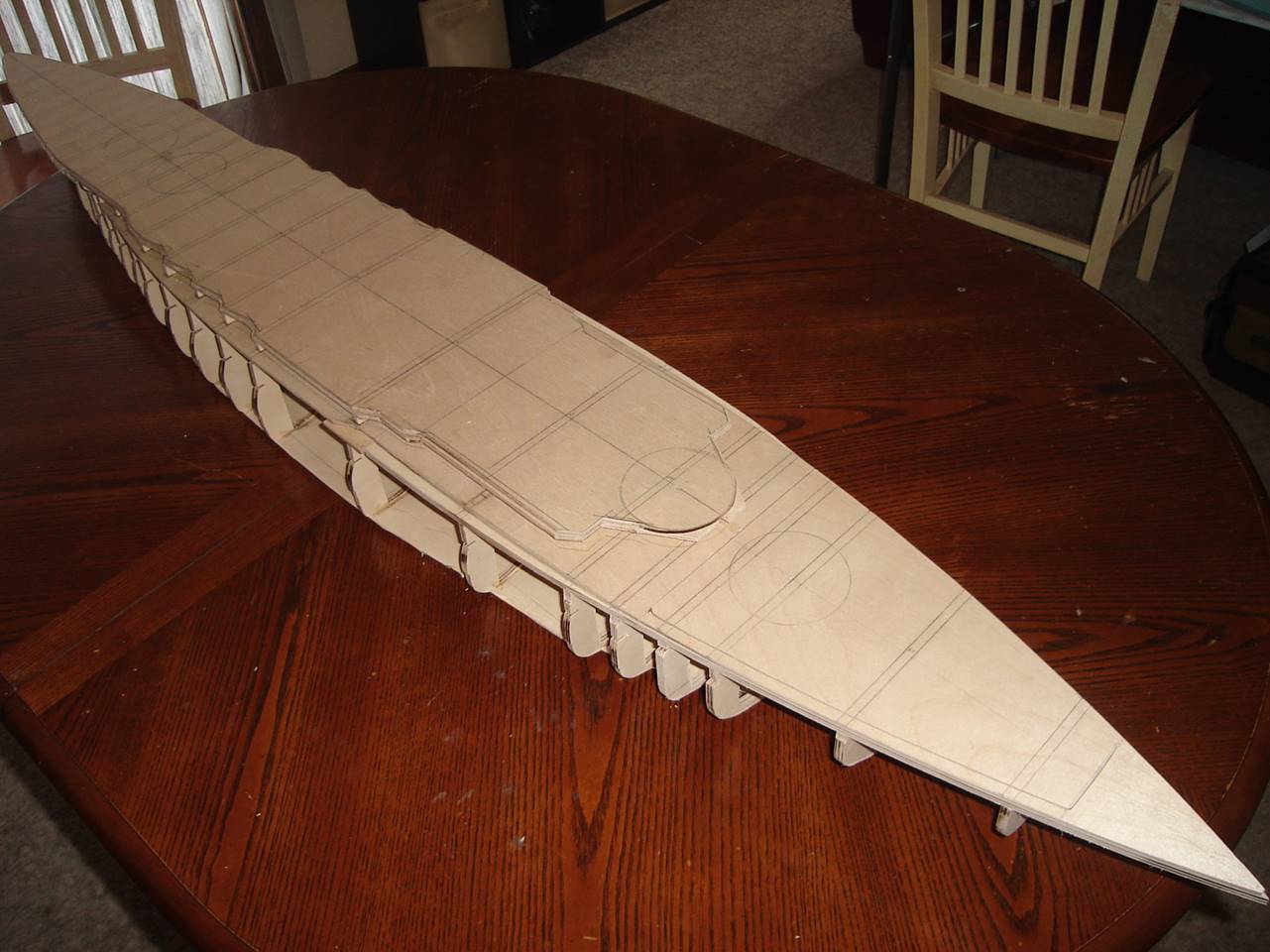

The decks are marked up with locations of ribs,

turrets, and the centerline. I would advise marking the underside like this,

not the top side unless you are planning on painting the deck. I realized my

mistake later on and erased and sanded the line I made.

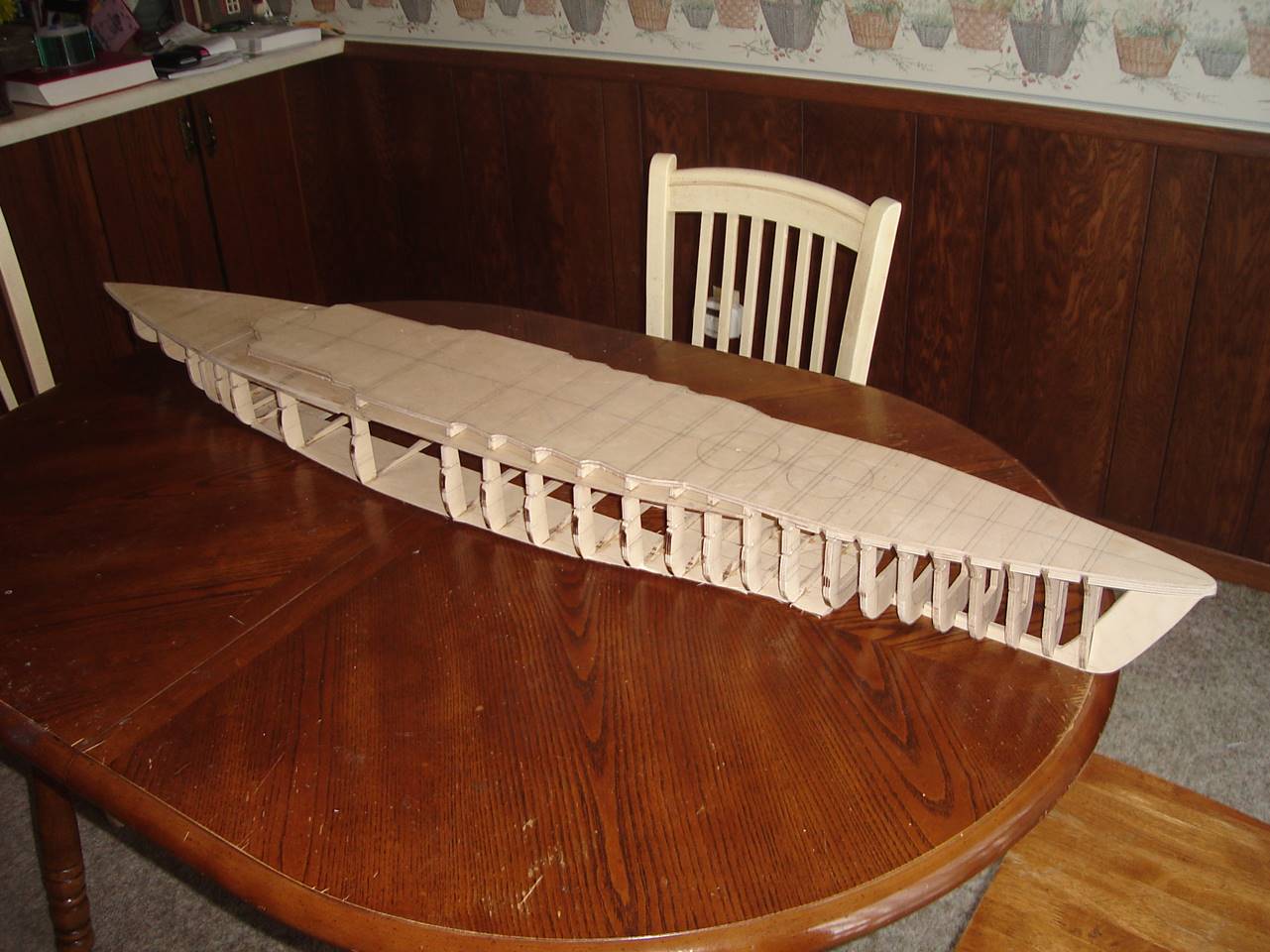

The ribs, deck, subdeck, keel in the bow, and base

board are all in place but the deck isn’t glued in yet. You can see there is

still sanding to do in the flare of the bow where the subdeck needs to be

sanded back.

This pictures shows how the base board is cut to

accept the ribs. I will end up cutting out the center part of all of the ribs

in the middle section completely out and flush with the base board. You can

save yourself some time by thinning out the ribs to the point where they are

structurally sound but will come out easily with just a little more cutting or

sanding once everything is glued in place.

Along the length of the ship you can see where I left

notches to accept an aluminum 1/8 thick stringer. Also at the bottom of the

penetrable window I left a notch to allow for the thickening that happens after

adding the fiberglass and other impenetrable material so there doesn’t end up

being a bump in that part of the hull, this makes for more seamless sheeting. I

often run a keel in the far bow and stern to hold the shape as it comes

together. The gaps are filled with balsa. The for bow 2 inches I would

recommend plywood rather than balsa as it holds up better over time, this area

of the ship will be shot repeatedly.

The way the stern most deck was designed is a bit of a

flaw, I wanted the raised stern turret to stay solid with the hull but this

made accessibility very difficult. After a season or two of battling I cut the

stern deck further forward and placed a new stern deck in so that the stern two

turrets are on the same piece of deck section. The far stern is notable for

having very few ribs apart from right where the turrets are. This is a bit of a

weakness in design to some people, but the total area of penetrable hull back

here is minimal due to the curvature of the bottom side where the props and

rudders go. And generally you will collect very few bb holes in that part of

the ship.

Another side profile shot.

Evidently, I did a ton of work before taking another

picture. The super structure is mostly ABS because it is very strong and fairly

easy to work with, it sticks together well with ABS specific solvent/cement and

can be cut with just a score of the knife and a folded and snapped along the

score. The lowest superstructure deck is wood because I wanted the wood colored

deck in that section. The 1/8 inch aluminum rod stringers are fit into place

here. The bow forward of A turret is all filled in with balsa, as are the

widest part of the bulges amidships. All of the bottom of the ship is covered

with 3 layers of 5-6 oz fiberglass cloth with epoxy (the 2nd layer

is fit at a 45 degree angle for strength). The entire ship is covered with

epoxy for sealing and protecting the wood, the epoxy is essentially a layer of

plastic that can absorb some energy before the wood gets damaged. I have found

that every 5-10 years it should be sanded down and re-done depending on use.

Side shot illustrates the same points as above.

The overhead view shows how I draw lines on the deck

to look like little planks. Also you can appreciate how the decks slide apart.

The bow section contains the forward 2 turrets and is held in place with

latches and by the middle section. The middle section with the superstructure

is one piece that goes all the way back to the 3rd turret, this

slides in and locks with latches as well. The stern most section was built to

leave the 3rd turret as continuous with the hull but was

subsequently cut out to be removable with the stern most deck section. In

generally it makes transportation and general maintenance easier to be able to

take the superstructure off with a large chunk of deck in the center of the

ship and leave the sections with functioning guns alone.

Side profile.

Bow section is seen with measuring tape. The original

cross brace made it very difficult to get the CO2 bottle in and out so it was

cut and a new one was placed right where the deck is cut behind the B turret.

The regulator is seen riding on top of the balsa block water channeling in the

extreme bow. The radio box is right behind the bottle. Later when this ship was

refit the bottle was moved to the center of the ship and the radio was moved

forward to sit under the bow two turrets.

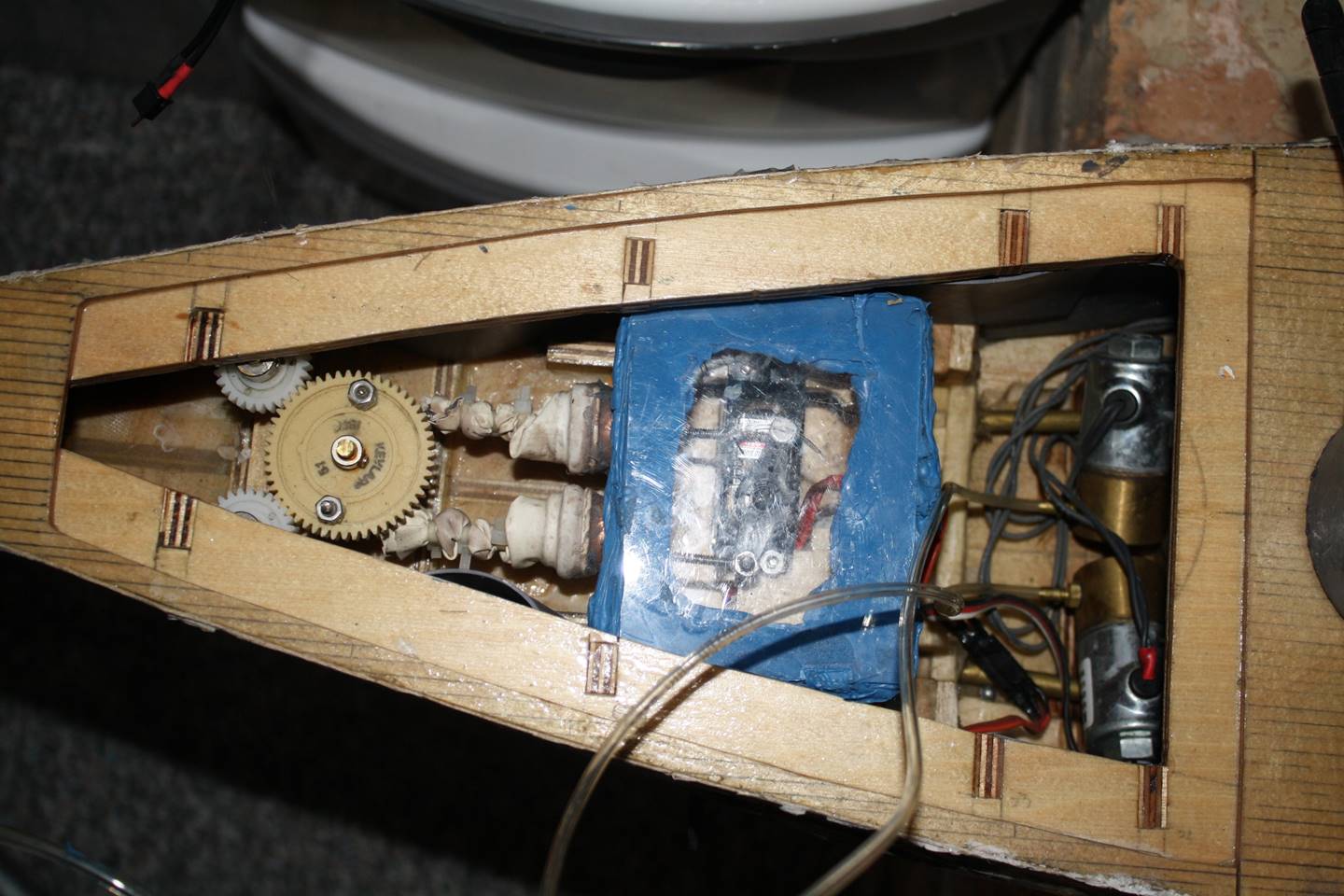

The radio box though in a different location now is

essentially unchanged from the original build. You can see the mount for the

back of the bottle sitting right in front of the radio box, also the solenoids

are seen in front of that, they were screwed to a little piece of mounting ply

wood. In the middle part of the ship you can see the step down to the lowest

part of the cut out water channeling. This is just a very thin piece of ply

wood, I believe 1/32 that was countersunk into the bottom of the base board

before being fiber glassed over the bottom. The water channeling is generally 2

inches wide and runs from B turret to C turret, which is similar in most of my

ships.

Here you can see the pump mount and outlet. The

solenoid was zip tied to the pump mount. The drive motors sit behind the pump.

The rudder box can be seen here. This ship required a

fairly high torqe servo that didn’t come in a water

proof version at the time. I think I could find a water proof servo that would

do the job now but the rudder box is still in the ship as original. There are

two push arms that go to a large gear, the large gear turns the two rudders.

There are balloons that have silicone sealing to maintain both flexibility and

watertight integrity. Again you can see that the original deck was cut to keep

the C turret in place however you can also see that it is essentially

impossible to get to the gear boxes for the drive train and this was later

corrected.

T

This is a midship section of the bulges, the balsa is

built up to the top of the water channeling and is about 1 inch or so wide. The

plastic rectangles were glued to the bottom to allow water to flow underneath

the original three 6 volt12 amp hour SLA bricks that powered the Nagato, but

still get the weight low in the ship. Without these water was trapping a bit

too much and the performance suffered as water wouldn’t flow very well to the

pump. A later refit changed to six 6 volt 10 amp hour NiMH batteries and the

plastic spacers were removed. The internal armor is shower pan liner and is

screwed to the wood ribs. I like to keep the wires and hosing out of the way by

running it along the outer edges of the top part of the interior, essentially

just below the subdeck when possible.

Height of the hull. I made the height as close to the

scale plans that I could, but at the end of the day are only as good as the

plan set.

Height of hull in the casemate deck.

Height of the hull after the step.

As I’ve discussed above, the ship as-built had some

major flaws in terms of accessibility, battery technology, and battling

theory/gun setup. It was later converted to NiMH with 60 amp

hours rather than the 36 of lead acid and the CO2 bottle was moved to

amidships. A second pump was added and one of the 5 guns was removed. To see

how the ship looks now see the Inside

the IJN Nagato article.